VariAS-Blocks

Typically provided with two ball valves for isolation and a needle valve for bleeding.

Standard Valve Head Unit

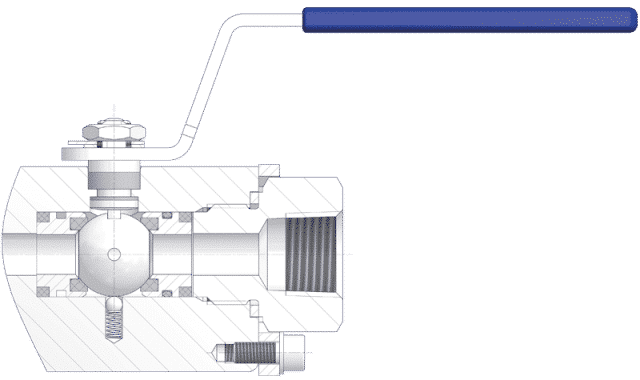

Ball Valve

Bore Size 10 mm (0.39″)

- Floating Ball Design

-

Body Cavity Relief

Ball with pressure relief hole -

Ball Valve Seat

– Soft Seated: Reinforced PTFE or PEEK.

Totally enclosed in seat carrier.

– Metal Seated: Ball and seats coated with

Hardalloy and Carbide Compounds. -

Stem Seal

PFTE or Graphite

- Anti-Blowout Stem Design

- Anti Static Design

-

Fire Safe Tested

Acc. to ISO 10497 / API 607 – With Graphite Seals only -

Positive Stop Pins

-

All Non-wetted Parts

In 316 Stainless Steel -

Lockable Handle with Color Coded Handle Grip

Isolate BLUE | Vent RED

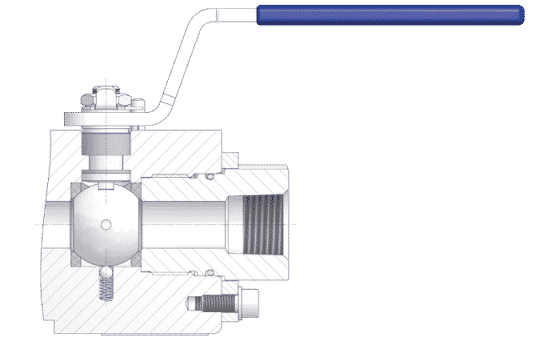

Ball Valve

Bore Size Ø 14 mm [0.55″] and Ø 20 mm [0.79″]

- Floating Ball Design

-

Body Cavity Relief

Ball with pressure relief hole -

Ball Valve Seat

Reinforced PTFE or PEEK -

Stem Seal

– PFTE or Graphite

– Lip Seal and FKM O-Ring Steam Seals optional

- Anti-Blowout Stem Design

- Anti Static Design

-

Fire Safe Tested

Acc. to ISO 10497 / API 607 – With Graphite Seals only -

Positive Stop Pins

-

All Non-wetted Parts

In 316 Stainless Steel -

Lockable Handle with Color Coded Handle Grip

Isolate BLUE | Vent RED

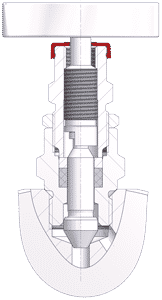

Needle Valve

-

Integral Valve Seat

Metal to metal seated - External Stem Thread

-

Interface of Stem and Needle

Is above the packing - Non-rotating Needle

-

Needle Seal

PTFE or Graphite

-

Back Seat

Metal to metal secondary needle seal -

Color Coded Dust Cap

For operation thread protection -

All Non-wetted Parts

In 316 Stainless Steel -

Lock Pin

Eliminates unauthorized removal of the bonnet