Monoflanges

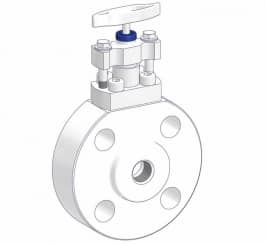

Process Monoflanges and Instrument Monoflanges are the most compact and cost-effective way for connecting process to pressure gauges or pressure transmitters.

Different Designs

AS-Schneider Monoflanges are available as Process Monoflanges as well as Instrument Monoflanges and are typically used in clean service. They are available in a Block, Block and Bleed or Double Block and Bleed configuration.

Process Monoflanges

They are designed to replace the traditional primary isolation valve. The primary isolate valve is of outside screw and yoke construction (OS&Y bolted bonnet) and is designed to ASME VIII and ASME B16.34 specifications.

The most frequently used DBB configuration is combining a primary isolate piping valve with the instrument block and bleed functions in one body. Bleed and secondary isolate valve are typically standard needle valve designs (screwed bonnet).

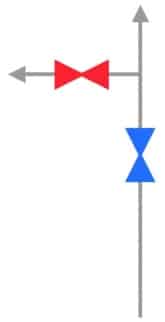

Instrument Monoflanges

They are close coupled to a pre-installed primary isolation valve to provide a compact Instrument Double Block and Bleed Valve or are used when primary isolation valves with an OS&Y bolted bonnet are not required. Instrument Monoflanges are provided with the standard needle valves (screwed bonnet).

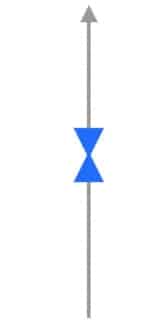

Block

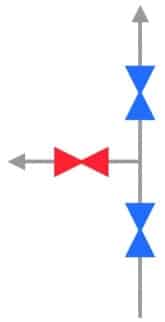

Block and Bleed

Double Block and Bleed